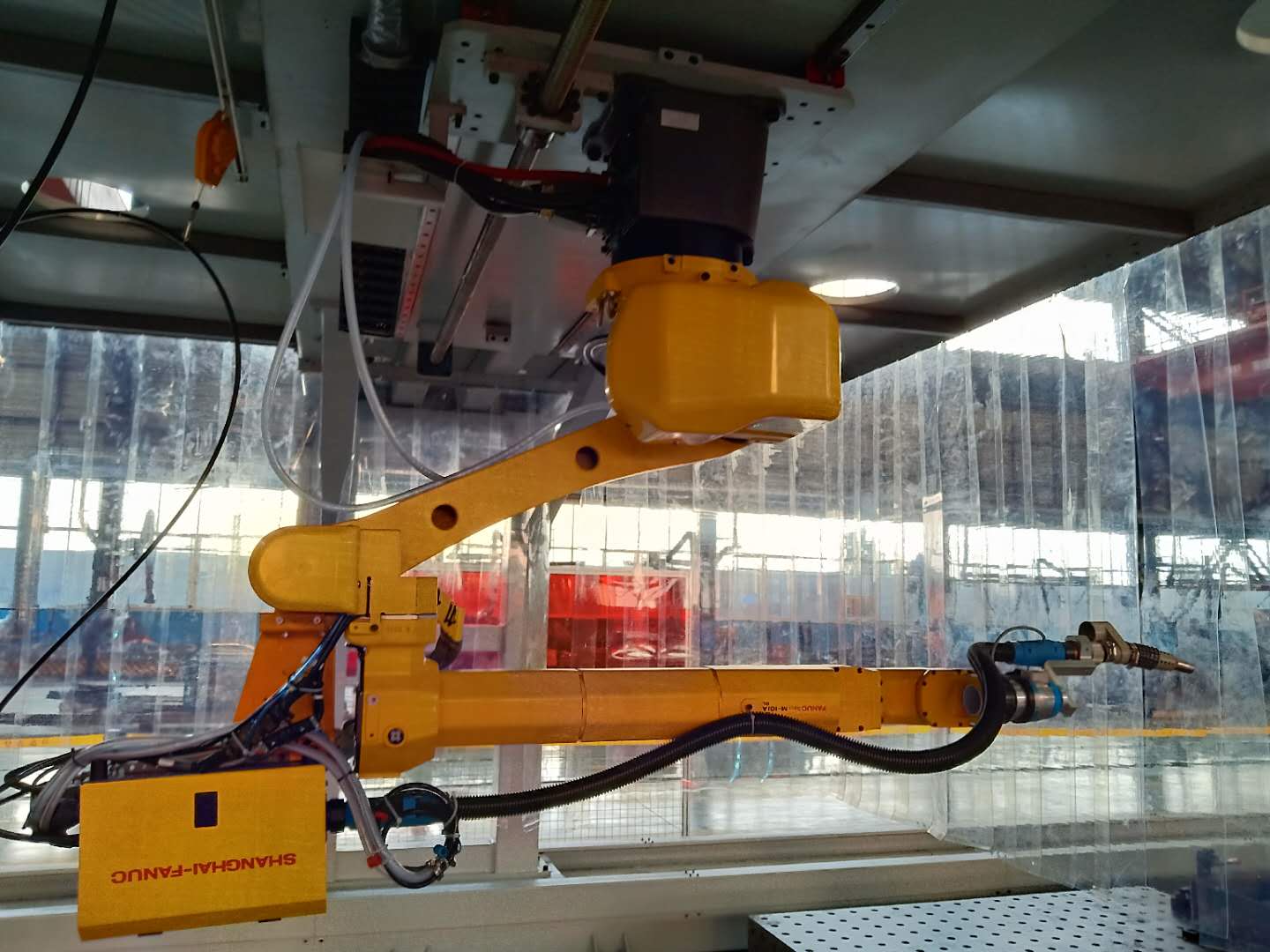

龙门焊接机器人-太阳成

the robot (gantry type) welding workstation has the functions of automatic welding and capacity information collection for the specified products, and meets the product drawings and process requirements. the welding station has good flexible produc...【】

24-hour service telephone

- introduction

- advantage

- parameter

- case

the robot (gantry type) welding workstation has the functions of automatic welding and capacity information collection for the specified products, and meets the product drawings and process requirements. the welding station has good flexible production and subsequent scalability, and can be combined with logistics transmission and information integration. control and other parts to achieve integrated integration control.

the software (including operating system, arc welding software, etc.) of all applications in the gantry welding station is all new. the use of high-precision servo motors, bilateral drive, precise control of the walking position, high accuracy (±0.3mm) in repeated positioning after long-span and long-distance multiple-round reciprocating motion. the gantry welding station can automatically proportionate the required products to improve production efficiency, reduce production energy consumption and production costs, and achieve intelligent production goals.

the gantry welding workstation achieves flexible production and meets the production status of the same line of products and the turnover of various specifications. the layout realizes the separation of man and machine, and the manual work area and the mechanical automatic work area are safely isolated. according to customer requirements, security measures such as safety fences and smoke evacuation devices are configured to meet the requirements of relevant safety and environmental protection regulations. with plc control, the operator can operate and master various working conditions of the equipment in real time, such as material running status, various process parameters, fault occurrence and causes.

1. laser guidance, laser ranging: real-time guidance of the robot's motion path, flexible production, reducing the accuracy of the welding workpiece and the precision of manual soldering.

2. automatic tracking, transformation of existing automated low-precision automation equipment, improve reliability, promote industrial restructuring, accelerate the upgrading of kinetic energy structure, and reduce the cost of upgrading industrial structure.

3. greatly reduce the labor intensity of workers, especially in harsh environments, improve the reliability and stability of equipment, increase the operating rate, and reduce production costs.

4. responding to world industry 4.0, responding to the national 2025 manufacturing, promoting the transition from labor-intensive to intelligent manufacturing, approaching the smart factory flexible system.

5. improve corporate image, seize opportunities, keep up with the country's real-time policies, promote the rapid development of enterprises, and become the leading innovative enterprise in the current era of technological change.

6. the robot integrates advanced manufacturing technologies such as precision, flexibility, intelligence, software application development, etc., through the detection, control, optimization, scheduling, management and decision-making of the process, to increase production, improve quality, reduce costs and reduce resource consumption and environmental pollution to maximize benefits.

7. wide range of applications the company's robots can be used in manufacturing, installation, inspection, logistics and other production processes for automotive and automotive parts, construction machinery, rail transit, low-voltage electrical appliances, electric power, ic equipment, military, tobacco, and finance. , medicine, metallurgy and printing and publishing, and many other industries.

8. the technology is comprehensive. the company's robotics and automation technology integrates and integrates multiple disciplines, covering a variety of technical fields, including industrial robot control technology, robot dynamics and simulation, robot construction finite element analysis, laser processing technology. advanced manufacturing technologies such as modular programming, intelligent measurement, modeling and processing integration, factory automation, and fine logistics.

9. open modular control system architecture: it adopts distributed cpu computer structure, which is divided into robot controller, motion controller, photoelectric isolation i/o control board, sensor processing board and programming teaching box.

10. networked robot controller technology: it can be used for communication between robot controllers and robot controllers with the host computer, which is convenient for monitoring, diagnosis and management of the robot production line.

-

暂无信息

官方服务顾问将在1小时内联系您,请保持电话畅通